Hp High-Temperature Grease

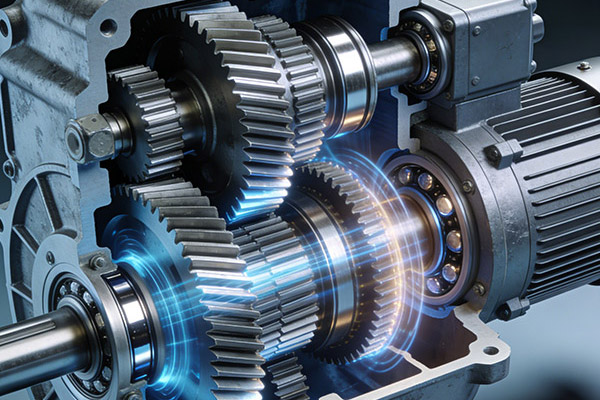

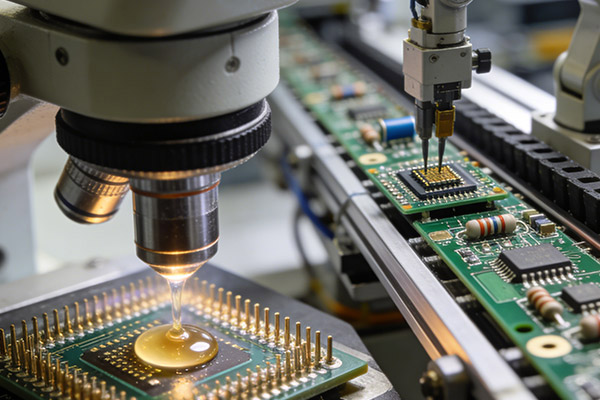

Suitable for the lubrication of various transmission mechanical components such as bearings, gears, and chains in high-temperature environments; can be applied in industries including metallurgy and mining, oil fields, machinery, steel plants, and transportation, adapting to the lubrication of motors, bearings, and gears under harsh working conditions such as high temperature, heavy load, and humidity; especially suitable for high-temperature bearings, such as rotating nozzle shafts of auxiliary boilers in large chemical plants, bearing sleeves of plastic extruders, induced draft fans of cracking furnaces, high-temperature bearings of regeneration gas compressors, stretching machines, hot-melt fans, heat-setting drying chambers, baking machines, high-temperature dyeing tanks, and other rolling bearings and sliding bearings of various high-speed machinery operating at high temperatures.