Composite calcium sulfonate grease

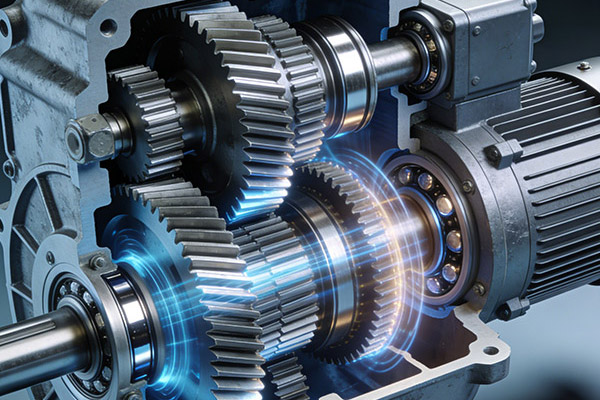

Composite calcium sulfonate grease is a new type of grease with comprehensive performance superior to other high-temperature greases. It has excellent high-temperature performance, water resistance, extreme pressure and anti-wear performance, and rust resistance, and its pumping performance can meet the needs of centralized lubrication. Its lubrication effect under harsh working conditions such as high temperature, high water content, and heavy load is significantly better than other lubricants. It is especially suitable for the lubrication of equipment such as steel continuous casters and rolling mills, helping to simplify the types of lubricants and facilitate oil product management.