High-Temperature Lubricating Grease

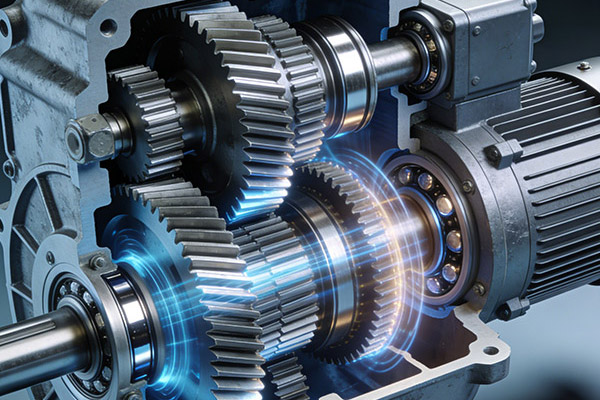

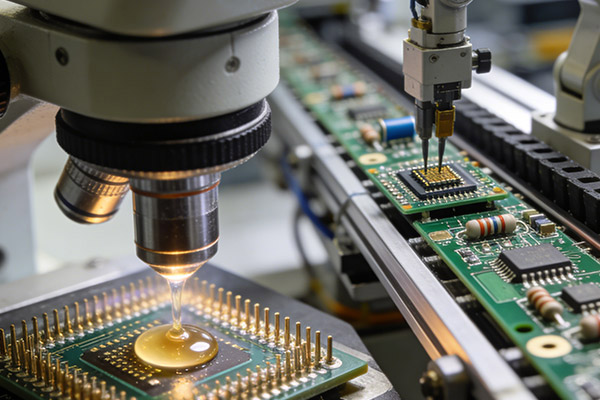

This product is a general-purpose lithium-based grease, belonging to a long-acting and multi-purpose grease. It can replace calcium-based, sodium-based, and calcium-sodium-based greases, and is an upgraded product of such lubricants. It has good water resistance, mechanical stability, rust resistance, and oxidation stability, and is widely suitable for the lubrication of rolling bearings, sliding bearings, and other friction parts of various mechanical equipment within the temperature range of -20℃ to 120℃.